JOSH AUDITORIUM

Client: Josh Motors

Location: Thodupuzha

Architect: Silpi Architects

Structural Consultant: Specialized Structural Designs

Pt Design & Contractor: Strands Post Tension Experts

Total Area: 28000sqft

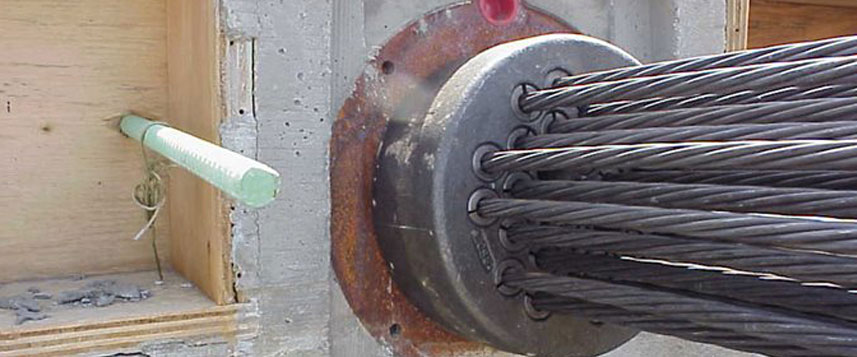

Post-tensioning is a method of producing prestressed concrete, masonry and other structural elements. The term prestressing is used to describe the process of introducing internal forces (or stress) into a concrete or masonry element during the construction process in order to counteract the external loads that will be applied when the structure is put into use (known as service loads). These internal forces are applied by tensioning high strength steel, which can be done either before or after the concrete is actually placed. When the steel is tensioned before concrete placement the process is called pre-tensioning. When the steel is tensioned after concrete placement the process is called post-tensioning.

The advantages of utilizing prestressed concrete and masonry have long been recognized by engineers. When a designer wants to take advantage of those benefits, they must determine whether the structure is to be constructed using the pre-tension method or the post-tension method. Pre-tensioning is generally accomplished at a manufacturing facility where concrete members are constructed in special casting beds with steel bulkheads that hold the steel in place while tension is applied. Concrete is then placed around the pre-tensioned steel and allowed to harden. The steel is then cut loose from the bulkheads and the entire precast concrete member is transported to the project site for assembly. This process may be limited to the use of standard shapes, and sizes that can be easily transported.

Client: Josh Motors

Location: Thodupuzha

Architect: Silpi Architects

Structural Consultant: Specialized Structural Designs

Pt Design & Contractor: Strands Post Tension Experts

Total Area: 28000sqft

Client: Christ University,Banglore

Location: Trivandrum

Architect: Silpi Architects

Structural Consultant: Jithesh Engineers,Kozhikode

Pt Design &Contractor: Strands Post Tension Experts

Total Area: 30400sqft

Client: Rajeev K Jayapal

Location: Thevera

Architect: Fahed Architects,Kochi

Structural Consultant: Synergy Engineers

Pt Design & Contractor: Strands Post Tension Experts

Total Area: 22000sqft

Client: Dalia Group

Location: Perinthalmanna

Architect: Silpi Architect

Structural Consultant: Jithesh Engineers

Pt Design & Contractor: Strands Post Tension Experts

Total Area:

Client: Sandeep

Location: Cherpulassery

Architect: Silpi Architect

Structural Consultant: Jithesh Engineers

Pt Design & Contractors: Strands Post Tension Experts

Total Area: 80000sqft

Client: Universal Construction

Total Area: 15000sqft

Structural Consultant: Basheer Sir,Kozhikode

Location: Kakkanad

When a concrete or masonry element is prestressed, it means that the steel is being tensioned and the concrete or masonry is being compressed. Compression is a force that squeezes or crushes and tension is a force that pulls something apart. As building materials, concrete and masonry are very strong in compression, but they are relatively weak in tension. Steel, on the other hand, is very strong in tension. Putting the concrete or masonry into compression and the steel into tension before any substantial service loads are applied puts both of these building materials into their strongest states. The result is a stiffer concrete or masonry member that is being actively compressed and has more capacity to resist tensile forces.